Understanding the Vital Role of Parts Crankshaft in Diesel Engine Performance

In the world of heavy machinery and automotive engineering, diesel engines stand out for their robustness, efficiency, and longevity. Central to their operation is a component often overlooked by many but crucial to engine functionality — the parts crankshaft. This detailed guide explores everything you need to know about crankshafts, their significance in diesel engines, the importance of high-quality spare parts, and how leading suppliers like client-diesel.com can provide you with the best components to ensure optimal engine performance.

What is a Parts Crankshaft? An In-Depth Explanation

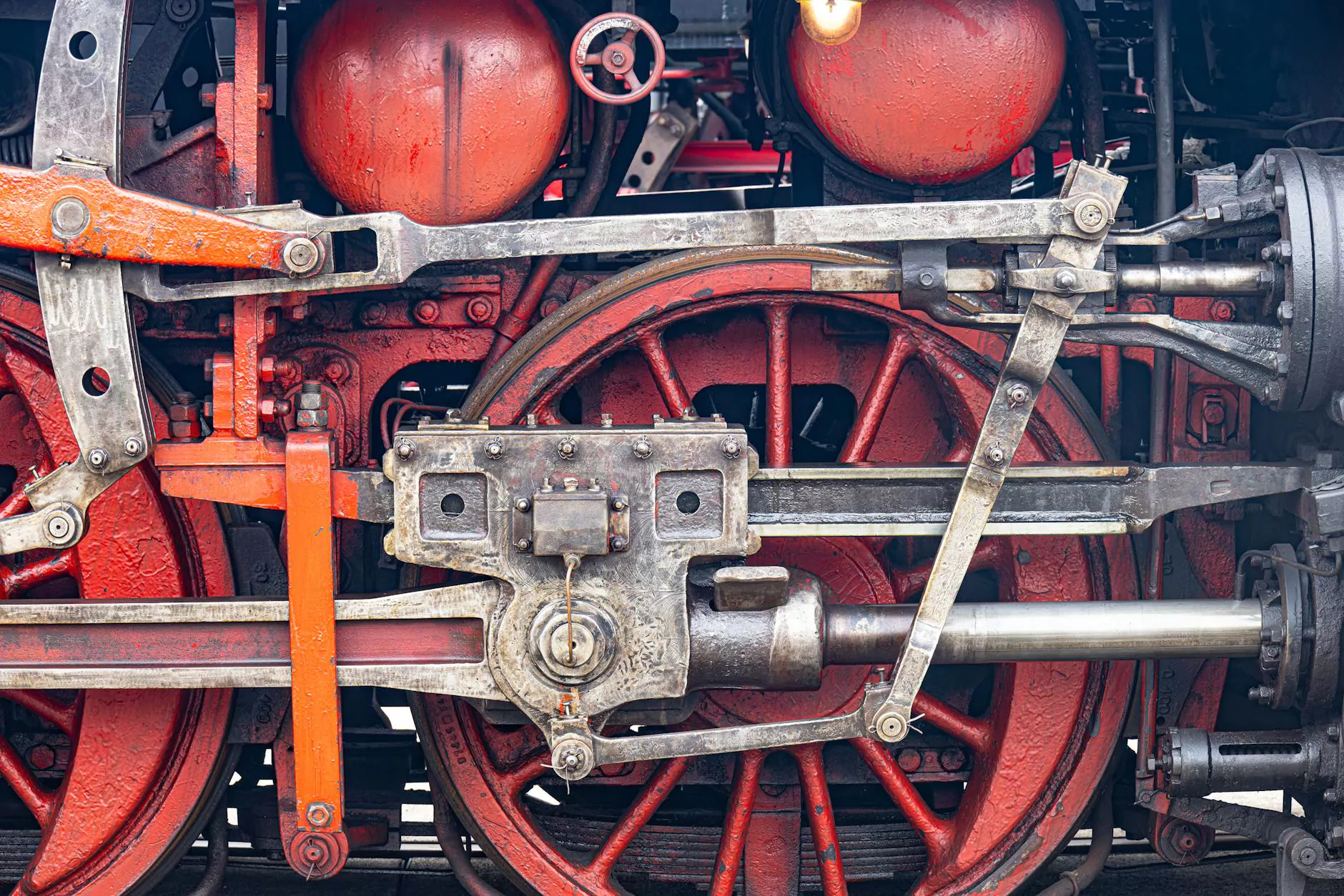

The crankshaft is a fundamental component of any internal combustion engine, especially diesel engines. It serves as the main rotating element that converts the linear motion of the pistons into rotational motion, ultimately powering the vehicle or machinery. The parts crankshaft include the shaft itself, along with associated components such as crankpins, main bearings, counterweights, and gear or pulley attachments.

- Crankshaft Designs: Typically, crankshafts are designed as either single- or multi-cylinder configurations, with multi-cylinder crankshafts being more complex and requiring precise engineering.

- Material Composition: High-strength alloy steels are favored for manufacturing crankshafts due to their durability, fatigue resistance, and ability to withstand extreme stresses and temperature variations.

- Manufacturing Processes: Modern crankshafts are produced using forging, casting, and machining, with forging being the preferred method for high-performance, heavy-duty applications.

The Critical Functions of Parts Crankshaft within Diesel Engines

The parts crankshaft play several vital roles that directly influence the performance, efficiency, and lifespan of diesel engines:

- Converting Linear to Rotational Motion: As the pistons move up and down, the crankshaft translates this linear motion into a smooth rotational movement that powers the vehicle.

- Driving Ancillary Components: The crankshaft also powers components such as the oil pump, water pump, alternator, and fuel pump through attached pulleys and gear mechanisms.

- Maintaining Engine Balance: Properly designed crankshafts include counterweights that balance the engine, minimize vibrations, and reduce wear on other engine parts.

- Absorbing Combustion Forces: The crankshaft endures immense forces generated by combustion, making material strength and precise engineering essential to prevent failures.

Why High-Quality Parts Crankshaft Are Essential for Diesel Engines

Investing in high-quality crankshaft parts is critical for ensuring engine reliability, safety, and efficiency. Inferior components can lead to catastrophic engine failures, costly repairs, and extended downtime. Here’s why premium parts crankshaft are indispensable:

- Enhanced Durability: High-grade materials withstand the rigorous stresses of diesel combustion, especially in commercial and industrial applications.

- Improved Engine Efficiency: Precision-machined crankshafts ensure smooth operation, reducing vibrations and energy losses.

- Longevity: Quality components extend the lifespan of the engine, providing a better return on investment over time.

- Compatibility and Fit: Authentic and properly manufactured parts crankshaft fit precisely, preventing misalignments and uneven wear.

Choosing the Best Parts Crankshaft from Leading Spare Parts Suppliers

When sourcing a parts crankshaft, partnering with reputable suppliers such as client-diesel.com ensures access to high-quality, reliable components tailored for various diesel engine brands and models. Here are key factors to consider when selecting a supplier:

- Product Quality: Look for suppliers offering OEM-grade or equivalent parts manufactured under strict quality control standards.

- Material Standards: The crankshaft should be made from forged or high-grade cast steel, with appropriate heat treatments for strength and durability.

- Range of Sizes and Compatibility: The supplier should provide various sizes and configurations compatible with multiple diesel engine models.

- Technical Support and Guarantees: Reputable suppliers offer technical assistance, installation guidelines, and warranties.

The Manufacturing Process of Crankshafts: Ensuring Quality and Performance

Understanding how crankshafts are manufactured underscores the importance of quality components. The manufacturing process typically involves:

Forging

Forging is the most preferred method for producing robust crankshafts, involving shaping steel under high pressure to improve internal grain structure, resulting in superior strength and fatigue resistance.

Casting and Machining

For less demanding applications, casting followed by precise machining is used. This method allows complex shapes but requires rigorous quality checks to eliminate internal flaws.

Heat Treatment

Post-manufacturing heat treatments such as carburizing or nitriding are essential for hardening the surface, improving wear resistance, and extending longevity.

Maintenance and Inspection of Diesel Engine Crankshafts

Proper maintenance of parts crankshaft is vital for preventing failures. Regular inspection can detect signs of wear, cracks, or deformation:

- Visual Inspection: Look for cracks, scoring, or corrosion on the surface.

- Vibration Analysis: Excessive vibrations often indicate a misaligned or damaged crankshaft.

- Ultrasound and Magnetic Particle Testing: These non-destructive tests identify internal flaws before they become critical.

If issues are detected, timely replacement with high-quality parts crankshaft from trusted suppliers ensures the continued reliability of your diesel engine.

Conclusion: Why Parts Crankshaft Are a Critical Investment for Diesel Engine Longevity

The parts crankshaft form the backbone of any diesel engine, translating combustion energy into mechanical motion essential for operation. Their complex design, material requirements, and manufacturing processes demand the highest quality standards to ensure durability and performance. Partnering with reputable suppliers like client-diesel.com guarantees access to authentic, precision-engineered components that keep your engines running efficiently for years to come.

Whether you manage industrial machinery, heavy-duty trucks, or marine vessels, understanding the significance of parts crankshaft and investing in top-grade components is fundamental to maintaining peak engine performance, reducing downtime, and maximizing your return on investment.

Explore Our Extensive Range of Diesel Engine Spare Parts

At client-diesel.com, we specialize in providing a comprehensive selection of diesel engine parts, including parts crankshaft, pistons, cylinders, valves, and more. Our commitment is to supply parts that meet or exceed OEM standards, ensuring your engines operate at their best.

Contact Us for Expert Advice and Premium Diesel Engine Parts

Need assistance in choosing the right parts crankshaft for your diesel engine? Our team of experts is here to help! Reach out to client-diesel.com today for personalized support, quality assurance, and fast delivery.